Electrical conduit installation is crucial for safeguarding wires from damage and environmental hazards, ensuring safe and reliable electrical systems. This guide covers materials, types, and best practices for proper installation.

1.1 Purpose of Conduit

The primary purpose of electrical conduit is to provide a protective pathway for electrical wires, shielding them from mechanical damage, moisture, and environmental hazards. It ensures safe and reliable electrical system operation by containing wires in a secure, organized manner. Conduit also facilitates future modifications, as wires can be easily added or replaced without damaging the system. Additionally, it plays a critical role in compliance with safety regulations and standards, such as those outlined in the National Electrical Code (NEC). By enclosing wires, conduit reduces the risk of electrical fires, shocks, and other hazards, making it an essential component in both residential and industrial electrical installations.

1.2 Types of Conduit

Electrical conduits are available in various types, each suited for specific applications and environments. Common types include PVC (polyvinyl chloride) conduit, known for its durability and resistance to corrosion, ideal for underground and wet locations. RMC (rigid metal conduit) offers maximum protection against mechanical damage and is commonly used in commercial settings. IMC (intermediate metal conduit) provides a balance between flexibility and strength, while EMT (electrical metallic tubing) is lightweight and easy to install, typically used in dry, indoor locations. Flexible conduits, such as LFMC (liquid-tight flexible metal conduit), are used for areas requiring bends and movement. Each type must be selected based on the specific requirements of the installation, ensuring compliance with safety standards and regulations.

1.3 Basic Materials

The choice of materials for electrical conduit systems is critical for ensuring durability and safety. PVC (polyvinyl chloride) is a widely used material due to its resistance to corrosion, lightweight nature, and affordability. For applications requiring higher strength, metallic materials like steel are utilized, offering excellent mechanical protection. Additionally, materials such as aluminum and fiber optics are employed in specific scenarios. Proper material selection must consider factors such as environmental conditions, load requirements, and compliance with local electrical codes. Each material offers unique advantages, making it essential to align selections with the specific demands of the installation. Adhering to material standards ensures a reliable and long-lasting electrical system.

Transportation and Storage of Conduit

Proper handling and storage of conduit are essential to prevent damage. Conduit should be transported securely and stored in dry, protected areas to maintain its integrity.

2.1 Handling and Transportation

Proper handling and transportation of electrical conduit are critical to prevent damage. Conduit should be carried on flat, stable surfaces or supported evenly to avoid bending or kinking. Avoid dragging or dropping conduit, as this can cause cracks or weaken the material. For longer lengths, use appropriate lifting equipment or dollies to ensure safe transport. When transporting PVC or metal conduit, secure it tightly to prevent shifting during movement. Additionally, conduit should be protected from extreme temperatures and moisture during transit. Always follow manufacturer guidelines for handling specific types of conduit, such as PVC or steel, to maintain its integrity and ensure safe installation. Proper care during transportation helps preserve the conduit’s quality and performance in the electrical system. Regularly inspect conduit for damage before installation to avoid potential issues.

2.2 Proper Storage Conditions

Proper storage of electrical conduit is essential to maintain its integrity and performance. Store conduit in a dry, clean, and well-ventilated area, protected from direct sunlight, moisture, and extreme temperatures. For PVC conduit, avoid exposure to heat sources, as this can cause warping or degradation. Metal conduit should be stored indoors to prevent rust or corrosion. Keep conduit off the ground using racks or stands to avoid water damage and pests. Ensure conduit is securely bundled or strapped to prevent shifting or bending. Avoid stacking heavy materials on top of conduit, as this can cause deformation. Regularly inspect stored conduit for signs of damage or deterioration. Follow manufacturer guidelines for specific storage recommendations, especially for specialized conduit materials. Proper storage ensures conduit remains in optimal condition for safe and efficient installation. Always prioritize protective measures to maintain the quality of the conduit before use.

Conduit Installation Process

Electrical conduit installation involves planning the layout, cutting, bending, and securing the conduit. Ensure proper alignment, safety, and compliance with local electrical codes and standards.

3.1 Step-by-Step Installation Guide

Begin by planning the layout and measuring the required conduit lengths. Use a vise to secure the conduit while cutting with a pipe cutter or saw. Deburr the edges to prevent wire damage. For bends, employ a conduit bender, ensuring smooth curves to maintain wire integrity. Mount the conduit using approved hangers or clips, spaced appropriately for support. Avoid over-tightening, which could cause damage. Connect conduit sections with fittings like couplers or elbows, ensuring tight seals. For underground installations, encase the conduit in concrete or use protective sleeves. Always follow local electrical codes and manufacturer instructions for specific materials. Proper alignment and secure fastening are critical to prevent movement and ensure long-term reliability. Finally, test the installation for any defects before pulling wires through the conduit.

3.2 Cutting the Conduit

Cutting conduit requires precision to ensure clean edges and avoid damage. Use a pipe cutter or hacksaw for metal conduit, while PVC conduit can be cut with a utility knife or specialized PVC cutter. Secure the conduit in a vise to maintain stability during cutting. Apply gentle, consistent pressure to achieve a straight cut. After cutting, use a file or deburring tool to smooth rough edges, preventing wire damage during installation. For precise cuts, especially in tight spaces, consider using a miter box or a conduit cutting saw. Always wear safety goggles and gloves to protect against debris. Clean, accurate cuts are essential for proper fittings and a secure electrical system. Avoid using damaged or dull tools, as they can create uneven or jagged edges, compromising the integrity of the conduit.

3.3 Minimizing Mechanical Damage

Minimizing mechanical damage during conduit installation is essential to ensure system integrity and longevity. Proper handling techniques, such as avoiding drops and impacts, are critical. Use appropriate tools, like conduit benders, to prevent kinking or crushing. When bending, follow manufacturer guidelines for radius and angle limits to avoid deformation. Protect conduit ends with plastic caps during transportation and installation to prevent debris entry. Avoid over-tightening fittings, as this can stress the material. For threaded conduit, apply thread compound to reduce friction and prevent galling. Regularly inspect tools and replace worn or damaged ones to avoid introducing imperfections. Use protective coverings or sleeves in high-risk areas to shield the conduit from environmental or mechanical stress. Proper storage and transportation practices also play a key role in preventing damage before installation begins.

Conduit Fittings and Termination

Conduit fittings connect and secure sections, while termination ensures wires are properly protected. Fittings like couplers, elbows, and connectors are essential for routing and maintaining system integrity and safety.

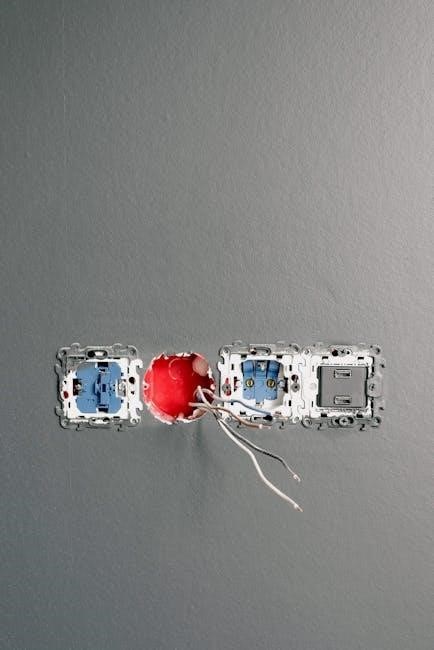

4.1 Types of Conduit Fittings

Conduit fittings are essential components that connect, redirect, or terminate electrical conduits. Common types include couplers, which join straight conduit sections, elbows for directional changes, and tees for branching circuits. Connectors secure conduit to boxes or panels, while adapters facilitate transitions between different conduit sizes or types. Materials vary, with PVC, metal, and galvanized steel being popular options. Proper selection ensures compatibility, durability, and compliance with electrical codes. Each fitting type serves a specific function, contributing to a safe and efficient electrical system. Understanding their roles is critical for successful conduit installation and system performance.

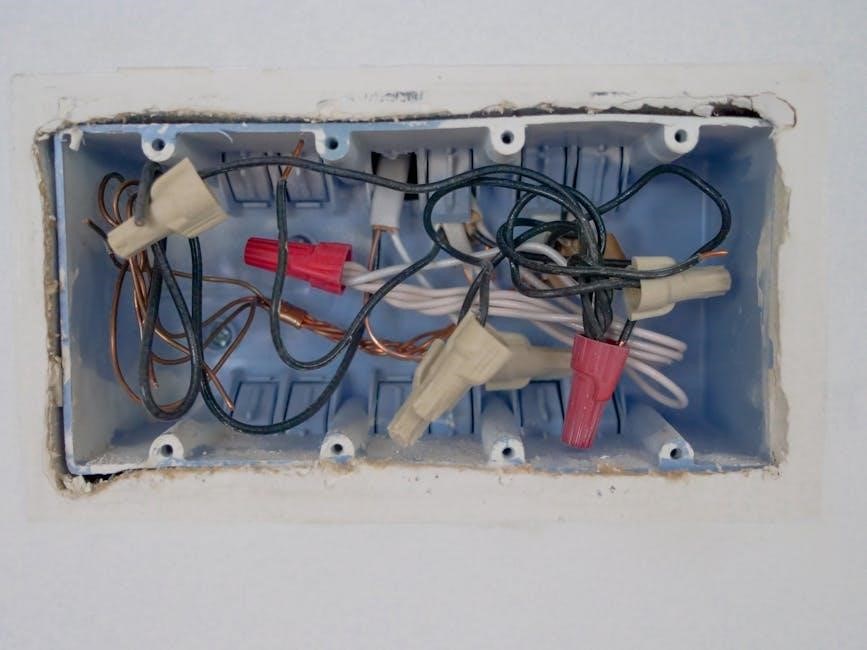

4.2 Best Practices for Termination

Proper termination of electrical conduit ensures secure and reliable connections, minimizing risks of damage or failure. It is crucial to follow best practices, such as ensuring conduit is properly secured to devices or panels to prevent movement. Connections must be watertight in wet locations, using appropriate fittings and sealants. Always use materials compatible with the conduit type and environmental conditions. Follow manufacturer instructions for specific termination requirements, especially for PVC or metal conduits. Testing post-termination ensures integrity and safety. Proper termination not only enhances system performance but also ensures compliance with electrical codes and standards, safeguarding the entire installation.

Cost Savings in Conduit Installation

Implementing cost-saving strategies in conduit installation can significantly reduce expenses without compromising quality. Planning and material selection are critical; choosing the right conduit type and size minimizes waste and optimizes performance. Precise sizing ensures you avoid over-specifying materials, reducing initial costs. Efficient use of fittings and avoiding unnecessary bends can lower material and labor expenses. Recycling scrap conduit material is another effective way to cut costs. Additionally, using cost-effective alternatives like PVC conduit for non-critical applications can save money. Proper installation practices, such as minimizing mechanical damage and ensuring correct termination, reduce the need for repairs or replacements. These strategies not only save money but also ensure a reliable and code-compliant electrical system.